DMG MORI is a global leader in high-precision machine tools, with operations in 44 countries and 17 production plants. Its expertise spans turning, milling, grinding, boring, ultrasonic, Lasertec, and additive manufacturing, delivering holistic solutions for industries including aviation & space, automotive & e-mobility, die & mould, medical, and semiconductor production. Beyond machines, DMG MORI offers full lifecycle services, from training and maintenance to turnkey automation solutions, ensuring that its customers achieve maximum productivity and efficiency.

In 2023, DMG MORI introduced Machining Transformation (MX), a comprehensive strategy designed to shape the future of manufacturing. MX integrates four pillars: Process Integration, Automation, Digital Transformation (DX), and Green Transformation (GX). These pillars aim to optimise production by combining multiple functions into single machines, leveraging automation to overcome labour shortages, and using digital tools and sustainability initiatives to enhance resource management and long-term growth.

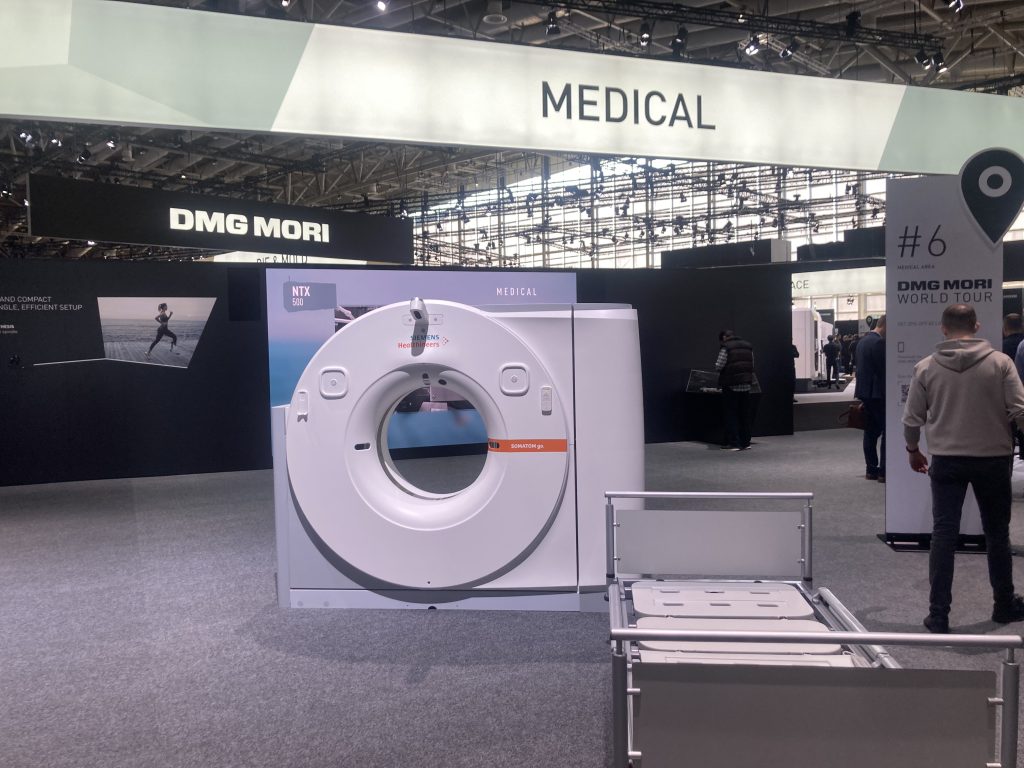

Steve Finn, Managing Director at DMG MORI UK, says the company’s appearance at EMO this year was focused on three focal points: technology, MX and 5+X industries (a reference to DMG MORI’s five main markets). Its presentation featured more than 40 high-tech machines, including 33 automated manufacturing solutions, covering all common machining processes. Crucially, eight of which were world premieres. “This shows that technology is increasingly becoming the driving force for change in manufacturing,” notes Steve.

DMG MORI’s latest machines demonstrate the practical benefits of MX. Multitasking solutions, such as the DMC 125 FDS duoBLOCK μPrecision, combine milling, turning, and grinding in a single clamping, increasing machine utilisation and reducing labour requirements. Automation is embedded across production lines, with AMR-series guided vehicles handling pallets, workpieces, and tools, allowing flexible, autonomous production. DX is powered by CELOS X, an intuitive, app-based operating system that supports planning, programming, and process optimisation, while GX ensures energy and resource efficiency through features like GREENMODE, cutting energy consumption by up to 30 per cent.

Steve says, “GX has the potential to preserve global resources, thereby protecting the environment, relieving the burden on people, and creating opportunities for further development. With our DMG MORI GREENMODE measures, we are consistently increasing the energy and resource efficiency of our machines, and we are continuously working on new solutions in this regard. The effectiveness of our existing energy efficiency measures and our calculation methods have also been confirmed by the renowned TUV SUD Industrie Service GmbH.”

Leading the Way

As a global innovation leader, DMG MORI is also pushing ahead with new development of green technologies. Steve says it’s also pleasing to see that many of “our customers use DMG MORI machines to manufacture highly innovative components for wind turbines and electric mobility, among other things, and profit from our extensive know-how in this field.”

Furthermore, digitalisation is a key driver of precision and efficiency in modern manufacturing, and it directly feeds into the success of GX. By leveraging digital technologies such as AI, IoT, Big Data, and Digital Twin, DMG MORI enables higher machining accuracy and optimised workflows, which in turn create competitive advantages. The integrated digital approach not only boosts productivity but also reduces energy consumption and CO₂ emissions, for example, by increasing productive spindle hours through faster programming at or near the machine. In this way, DX automatically promotes GX: improvements in precision, efficiency, and process control directly translate into reduced waste, lower energy use, and more sustainable production.

Automation is another cornerstone of MX, offering manufacturers measurable advantages in efficiency and flexibility. As Cornelius Nöß explains, “Against global competition, companies face the challenge of implementing efficient production. In the 21st century, machine tool automation is the key to economical manufacturing processes. Automation solutions used to be a topic primarily for large series production, but the trend today is towards more varied production with ever smaller batch sizes. As a leading machine tool manufacturer, DMG MORI will demonstrate how to ensure long-term competitiveness by using automated production.”

By automating CNC machines, manufacturers can maximise the use of their production capacity. “This applies to unmanned night and weekend shifts as well as to day-to-day business, where the automation is set up with new orders while metalcutting is in progress. This reduces throughput times and gives the staff freedom and flexibility to carry out skilled tasks such as CNC programming, work preparation, and quality control,” Nöß adds. In practical terms, this means that machines continue working efficiently even outside standard hours, while highly skilled staff focus on tasks that add greater value to production.

Workpiece handling systems are a key element of this automation. Nöß explains, “In modern manufacturing, automating recurring workflows is one of the most common ways to optimise processes. One of the main tasks of such automation solutions is reliable workpiece handling, in other words, the autonomous transport of raw parts from a workpiece storage system to a lathe or machining centre. Following machining, the parts must then be removed — usually by means of a robot or gantry loaders — and stored in workpiece storage. The process can be individually adapted depending on the application. This means, for example, that downstream processing steps such as deburring, measuring, and labelling can also be integrated into a workpiece handling system.”

New Technology

“As part of the Machining Transformation (MX), with which DMG MORI is paving the way to the future of manufacturing, automation solutions have a firm place,” notes Cornelius. “They create personnel capacities for qualified activities and optimise machine utilisation even in unmanned shifts.” At EMO 2025, the machine manufacturer showcased a variety of automation solutions and presented a dedicated automation hub. The exhibition included pallet handling systems such as round pallet storage, the PH Cell series, and the WH Cell workpiece handling system, as well as the robot-based Robo2Go models and the MATRIS system.

Among the recent world premieres unveiled by DMG MORI in 2025, the DMC 65 monoBLOCK 2nd Generation and DMC 55 H Twin highlight precise 5-axis simultaneous machining, ideal for aerospace and complex industrial components. The ULTRASONIC 60 Precision combines 5-axis milling with ultrasonic-assisted precision machining, and the NLX 2500|1250 universal turning machine offers versatile automation and high productivity. Each machine exemplifies how MX principles — integrated processes, automation, digital connectivity, and sustainability — are shaping the next generation of manufacturing solutions.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News