The Japanese construction industry experienced its first major boom over 50 years ago with the Tokyo Olympics and that has continued until today, but it is expected to plateau by 2040 because of the demographic crisis. How do you assess the current health of the construction industry in Japan?

The number of people working in the industry sector is declining sharply and many very skilled people are in their fifties, sixties, and even seventies. Furthermore, younger people these days are not willing to do what can be difficult and sometimes dangerous construction site work. Therefore, it is becoming more and more difficult to find young people in our industry. We’re very fortunate to have had many hardworking and skilled individuals in the past who helped build Japan. The question is whether we can sustain it. Also, you may have heard that since last year, we have had a cap on overtime. This limits the amount of work that can be done. In the past, Japanese people were criticized for working too hard and too much. But that’s how things got done in Japan.

That combination of fewer workers working fewer hours means we have to use new technologies as much as possible. That’s why I have a bunch of Kawada Robotics (Kawada Group’s robot manufacturing company) engineers working with the construction department to come up with labor solutions. In Japan, many instructions and documents are still paper-based, so that is something else that has to change. We need to make things digital. Aging society problems and labor shortages are big problems in Japan, but it’s a good chance for Japan to really change.

Japan’s construction industry has long followed a scrap-and-build policy whereby old buildings are demolished to rebuild new infrastructure. However, there is an increased focus on the renewal of aging infrastructure these days. How do you see this opportunity to focus more on renewable infrastructure rather than use scrap and build?

For buildings, we have even scrapped 30+ story high rises in downtown Tokyo and I think that’s partly because those buildings did not comply with the current seismic laws, which I believe came after the big 1995 earthquake in Kobe, so those probably had to be done. Some private sector buildings still focus on scrap and build, but things like roads, tunnels, and bridges, are moving towards maintenance and repair to allow that infrastructure to last another 50 years.

For our industry, which is building bridges, the business model has long been to make money at the factory. The construction site is where we just take what we made at the factory and install it, so that’s how Kawada Industries and other steel bridge companies operate. I just became the chairperson of the Japan Bridge Association this June, and although the total yen amount of infrastructure investment is going up, new bridge tonnage is at a record low, and it is expected to be even lower. Kawada Industries actually had the biggest share of winning contracts last business year, but our factories are not full. They were kept busy for about ten years until last business term, but now that is waning. It is time to change the business model from relying solely on new bridges to focusing more on maintenance and repair work.

Last year, Japan Bridge Association had a trip to Scotland. The UK in the past was considered the world’s bridge technology leader. Amazing technologies came from there – bridges like the Forth Bridge and the Humber suspension bridge. But several years ago, the last standing bridge company, Cleveland Bridge, failed, so they have no more bridge companies there. Because of that, whenever there’s a bridge that needs to be built or a bridge that needs repairs, there’s nobody in the UK that can do it. I understand companies outside of he UK now do that work. We are worried that a similar thing can happen in our country someday. So the association is lobbying the government to keep building more bridges so our skills will be maintained, but it’s already tipped and the industry has to change. There’s no way the current system and situation can be sustained.

Japan has great anti-seismic technologies for both new builds and retrofitting. Of course, Japan is at the intersection of three seismic plates, so it has a lot of experience dealing with these incidents. If you look at the so-called Pacific Ring of Fire, you have many countries in Southeast Asia, like the Philippines and Indonesia, that are growing fast and have new infrastructure demands. Do you see those markets as a business opportunity, especially as a Japanese company with such strong anti-seismic technologies?

During my grandfather and father’s time in the 1970s and the 1980s, our company worked on projects such as the Manila Metro System in Philippines and steel structures and bridge projects in the Middle East. But, we have been away because we were so busy with the domestic infrastructure projects. However, now that those projects are no longer ongoing, I think it’s a good opportunity for Japanese companies to pursue projects in other countries.

Japan is often criticized for being too expensive, but actually the prices are usually reasonable in comparison because a lot of projects that foreign competitors end up winning don’t actually get finished, or they end up costing much more than their estimated cost. In contrast, Japanese companies give fair and conservative prices. We probably need to help foreign countries understand that our prices really are reasonable. So, yes, for those Ring of Fire countries, Japan should be working on infrastructure projects because it has the most experience and technology.

You mentioned the different labor challenges in the construction industry and in response, many companies are now pushing for more safety, inclusion, and a better working environment. Your company is also part of the Valuable 500 initiative, which aims to put disability inclusion on corporate leadership agendas. Can you talk about the initiatives you are putting in place to attract and retain new talent?

We joined the Valuable 500 several years ago because I really like the initiative. Saying that, we have a very limited number of physically handicapped people in our company. However, one thing we are doing is helping with Avatar Robot Cafe DAWN ver.β, which is a unique dining experience where robots, controlled by individuals with disabilities, serve customers. It’s run by Ory Lab. founded by Kentaro Yoshifuji and the robots are communication robots. They can move. They can look at you. They can talk to you. The cafe employs about 100 people that cannot leave their homes and they operate the robots remotely, so they are not automated AI robots. We’re not employing these people at our companies, but we are helping the cafe and we sponsor the operation a bit. It’s a very interesting way to work and I think that way of working will apply to other businesses someday.

Mr. Yoshifuji goes by the nickname Ory-san because he’s amazing at origami. He and I met in 2019. I knew he was working on this café, and then he told me that one of the robot operators used to be a great barista, but one day she developed ALS. When that happened, she was preparing to attend a barista competition, but the condition made it difficult for her to continue. Ory-san told me he wanted her to become a barista again, this time through a robot. Our engineers worked with her to develop that robot, with her input about things like what temperature the water should be, how to add the water, how many minutes to wait, how slowly to press down the French press, and how to pour, etc. Our engineers programmed the robot so she can remotely operate it to be a barista again, which she does a few times per week from her home.

So, that sort of effort goes with the Valuable 500 idea and I think if she can make coffee with a robot from her home, I want someday to develop robots that some of our people can just remote control from a comfortable room to do construction work or quality control. It could also allow us to keep older workers who can’t or don’t want to work in the harsh construction site environment.

Another issue confronting the construction industry is green construction and sustainability, with a movement to reach net zero by 2050. You already implement some new technology to support green efficiencies. For example, Midori-chan is a greening system for building rooftops and roadside greening projects. Can you tell us a bit more about how you are approaching the challenges and opportunities of implementing green construction?

One big part is materials, especially steel. That’s considered Scope 3 emissions in the sustainability terminology for us, and we have to rely on suppliers like NIPPON STEEL and JFE for that and they’re working hard on sustainable materials. We are working on one bridge project using what they call green steel, so that’s already underway, although it’s still more expensive. Whenever we have the chance, we try to use that material, but it is not something we can really control ourselves.

Another initiative we are undertaking is the installation of solar panels at all three of our factories. Our Tochigi Factory is also using a hydrogen generator which is powered by excess energy from our solar panels. We can also use hydrogen to cut steel material. Actually, the city of Otawara, where our factory is located, is planning to introduce a hydrogen fuel cell bus. We may be donating some of the hydrogen we generate.

We also have a plan in Toyama to help plant trees in one part of a forest that was not in great condition. There is actually a problem with bears coming into the city because they don’t have enough food in the forest, so I want to plant persimmon, chestnut, and acorn bearing trees so they’ll have more food and will stay up in the forest. Of course, those trees will also help reduce CO2. That project is on hold now because I wanted our employees to plant the trees, but now everybody’s afraid to go to the forest because of the bears, so it’s a catch-22. I think the new plan will be to just ask the forestry people to plant the trees.

We don’t have many electric cars, but we changed all the salespeople’s cars to hybrid cars and we do whatever else we can to reduce CO2. We have a sustainability team who monitors it and tries to find new trends and ways we can reduce emissions further, so we’re committed to the Japanese government’s reduction goals of 46% or 47% by 2030 and zero by 2050.

Your company is a leader in steel bridge construction in Japan. Can you talk about the key technological capabilities that help you stand out as a leader in this market?

In the world of bridge contracts, we are considered a superstructure maker. Pillars and foundations are usually given to general contractors such as Kajima, Taisei, and Obayashi, whereas we do the superstructure. Most bridge companies do only steel bridges or only concrete bridges, but Kawada Group can do any kind of bridge. In fact, Kawada Construction, which used to be Kawada Industries’ construction department, but was spun out. It is now one of the largest prestressed concrete companies in Japan. Because these two companies work together, we can construct both steel and concrete bridges. That is why we could develop a hybrid bridge – PreBeam – which is our original preflex bridge. We also have a steel-concrete hybrid deck system called the SC Deck. So that is one of the unique things about Kawada Group.

For steel fabrication for things like dome stadiums and high rise buildings, we are one of the very few companies in Japan that can both fabricate and erect. Most companies just make the steel columns and the beams and they put them on a truck and send it to the construction site, but we can do both. We will make it for you and we can erect it, so we’re a one-stop shop. Often, problems at the construction site arise because construction people say that the steel parts are of bad quality, so it takes more time to adjust things at the site. Of course, the factory people say they sent good quality products and blame the site crew. In our case, general contractors can just talk to us directly since we do both.

Our company’s background was always steel. My great grandfather was a blacksmith and my grandfather was a plant engineer that used steel. Interestingly, my father studied French at university, so he wasn’t originally an engineer at all, but he joined the company and learned on the job and then ended up getting a doctorate in bridge engineering from University of Tokyo. At one point, he decided that a bridge was just a bridge. The customer wants to go from this side to the other side, so it doesn’t matter if it is a steel bridge, a concrete bridge, or a hybrid bridge. In that way, he was really thinking outside the box. That’s why we can do both, and I think that type of thinking is still found in our company.

My father also decided to get into aviation business in 1980s. I became an aerospace engineer because my father said we were going to develop a helicopter. We had to cease that work after the Japanese economic bubble burst, but that was really creative thinking for a construction company. I took it from there and into robots, and now robotics engineers are at the construction sites and our factories mixing with the construction people.

3D welding mask System

We did construction the same way for 100 years, but the robot guys are questioning the conventional ways. Many older, skilled workers prefer ways they have always done, but the younger ones are much more open to change because it makes things easier for them. For example, if a young person wants to be a welder, the experienced welder would say that it will take at least ten years to get to his level and the young one doesn’t want to do that so he quits. That is why we came up with a welding mask that lets you see what’s going on so it is so much easier to learn how to weld. I believe this is a good example of the strength of the Kawada Group.

You mentioned the importance of new technology and innovation to support the growth of the construction industry. You discussed robotics, but you also have several other interesting technology projects. How do you think new technology is affecting the current construction environment and how are you integrating different technologies to make a good platform?

To answer the second question first, it is very difficult to integrate it because it is very segmented. There are real estate developers, architects, general contractors, and subcontractors like us. They all say things like, we have to do Building Information Modeling (BIM), and you should be able to design it, and we can get it made exactly as the software says. However, a CAD program or BIM systems for different players are not the same because they all have their own way of doing things and they have different machines. That is why it’s very difficult to integrate things. That’s definitely true for the private sector. For the public works sector, I think it is a little easier because the government can dictate how to do things. Japan Bridge Association is working with the Civil Engineering Consultants Association to do more digital data transfer to make things easier, so that’s the integration part.

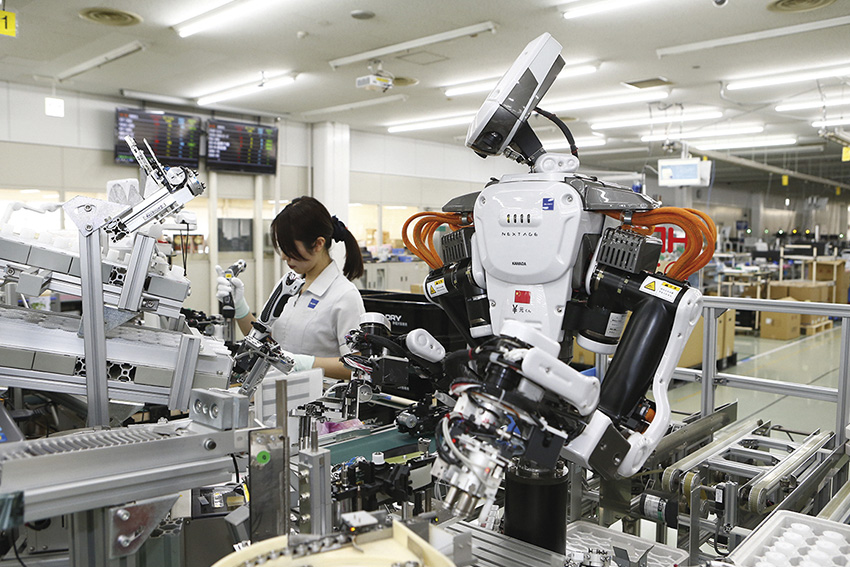

Collaborative robots working with people NEXTAGE (GLORY Ltd. Saitama Factory)

As for the use of technology for the current construction environment, I think Japan is a very good place implement it. For example, every time I go to Europe and talk about robots, I get questions about when the robots are going to revolt and kill us all, whereas here we grew up with a technology-based culture so we think of robots as our friends and things that make our lives easier. Combine that with the labor force getting smaller and people getting older, Japan is well poised to lead. Even former Prime Minister Abe some years ago said the demographic issues are also an opportunity. If we can overcome that problem, we will be the first in the world to do it. Mr. Abe even came to visit us and one of our NEXTAGE launch customers. That place got twenty NEXTAGE robots and they have 30 employees, but they didn’t fire anybody. Instead, the robots are there working and the people were retrained to higher paying jobs, so now 30 people are effectively doing the work of 50 people with nobody losing work and they’re getting paid better and the company is more efficient.

AGVs passing through a narrow inspection road

What I’ve seen in the manufacturing sector will happen in the construction sector with automation. It’s much more difficult with the weather issues, but we’re trying to see how we can do it. For example, when we were fixing the bridge in Osaka, we developed an automated guided vehicle (AGV) that can carry heavy weights that used to be carried by people, so that saves them a difficult job that can lead to injuries and frees them up to do other things.

We are also coming out with a pillar joining system. When you have a high rise building and you put in long columns, they have to be perfectly vertical, and they are connected, so if you move one, then another one shifts, so you need a group of people to coordinate that. Therefore, we’re trying to automate that using a laser, angle checker, and data analysis.

A device for guiding suspended loads with ropes“EG-Guide”

When we take a long bridge beam to the site and you get the crane to lift it, it can be very unstable. Several people are required to pull, push, and coordinate it. Now, we’re automating that with two AGVs and ropes that can be controlled by just one person.

So, using several people can become just one if you use appropriate technology and we’re having fun with what we’re doing.

You mentioned working on helicopters before the economy crash in the 1990s and I read you were the first in the world to use helicopters to help construct bridges. I’m curious about the use of drones these days, seeing as they now seem to be a solution for everything from taxis to construction sites to recreational vehicles. What is your take on using drones for heavy construction?

Well, an AGV is a ground drone, so I think both flying and ground drones will be very important, especially coupled with precision GPS, so you pinpoint exactly where things are. As an example, Kawada Technosystem (Kawada Group’s ICT company) developed software using a drone to be used if there’s a landslide. You fly the drone there and scan the area and it can quickly calculate how much the actual land slide area is, so I think drone use is very important.

AI has become an important aspect of innovation in all industries, not just the construction industry. It can help accelerate processes and analyze massive amounts of data. How are you integrating AI in your current system or processes?

I just led an AI x Robot panel session a couple of weeks ago at the GLOBIS business school. I’m not an AI expert, but I regularly use it to help me refine my reports and get some information. I think AI can be a great help for anybody these days. As for our company, our engineering department is currently trying to use AI to do design. Another use might be a knowledge base of important onsite knowledge and skills. For example, sometimes construction management goes well because a skilled person has a hunch that there might be something wrong and can fix the situation, but if he’s sick and he can’t come to work, that site is in trouble. A knowledge base with his and other skilled employees’ knowhow can help things go smoother, even with less experienced workers.

As another example, consider construction site accidents. If there is a bad accident, I get the report. But there are many events that we call “hiyari hatto”, which means near miss. These are events where luckily nothing bad happened but could have. Those incidents are recorded and filed, but historically were not used. For one accident, there might be ten or more near misses, which without luck could have been bad accidents. So if we can put those in AI maybe we can create a system where we can enter the details of the day’s construction activity and conditions and it will predict what kinds of accidents are more likely to happen. I’m not sure if that’s an AI use or big data use, but the knowledge of the people and of past events can be used much more easily now.

So, as we are not supposed to work as long and older skilled engineers and workers will leave the workforce in the coming years, if we can get their knowledge to more younger staff, that will definitely help. Because this effort will make things easier and safer, it will also help attract younger people to work for us. This is very important because our HR department is always having trouble getting and retaining talent.

In December 2024, you released your first English IR reports for foreign investors. In 2023, Japan saw a record-breaking number of JPY 50 trillion in foreign investment and the government wants to reach JPY 100 trillion by 2030. What are you doing to attract foreign investors to your company?

As the president of Kawada Group, I value the spirit of “Happo Yoshi”, or “Eight-Way Good”, and it’s our unique idea of sharing long-term profits with all our stakeholders, including investors or shareholders.

We do not look for quick returns, but have long-term thinking. Everything we have done, we first prove that what we do contributes to the society and customer needs. Investing in technologies and doing good jobs to satisfy customers needs lead to profits.

Especially, “our employees and all those who work for Kawada are empowered and feel safe”, “our quality will surpass customers’ expectations”, and “we make sure our customers are happy and our employees feel well-paid and empowered to do a better job” – with these as starting points for creating a virtuous cycle, I believe it’s Kawada’s role to contribute to “Happo”, or all of our stakeholders.

Kawada is a very unique and interesting company group. It would be great if investors who share the values of “Happo Yoshi” could consider investing in us.

You mentioned that you’re slowly trying to increase your overseas business and that you see it as eventually becoming part of your group’s day-to-day operations. I’m curious about how that takes place. For example, there is a traditional technical assistance protocol where you’re not the prime contractor in the country, but you’re working with a local partner to complete the project. Alternatively, there is a technology collaboration where you can share some of your technologies with overseas partners. Could you tell us which strategy you’re focusing on or which particular product you see as having the most potential for overseas markets?

We’ve done a lot of overseas projects in the past, but those are projects where we established our organization there, we sent some people, we got the work done, and we left. That was always the way we did things. Currently, the world is facing very disturbing times, I have to think twice before sending our staff to ensure safety and avoid risks. Therefore, I think it’s better if we find good local business partners.

Actually, for our robot business, we have a partnership in Switzerland with a company in Lausanne named Rollomatic. They handle and promote our NEXTAGE robots and they are excellent. So we don’t have our own office there, though our team communicates with them online often. I think that is one way to do things.

In the past, I have talked with a professor in Ireland who was very interesting because he has technology to make plant roots stronger. So I thought that would be good to mix with our water saving greenery system, Midori-chan for desert-like climates. Although at the end, it did not work out, that’s another type of international partnership that could be good for both sides.

So, to answer your question, what I want to do is find good business partners wherever it makes sense. I’m especially keen to market Midori-chan overseas because I know it’s good for places like Africa and the Middle East, although we still don’t really know the market. Midori-chan was developed here for rooftop gardens to save water. That was the selling point here, but when I talked to people in Africa and also in California, they seemed interested in knowing if it could help grow crops with less water. So, we have to find partners that know the needs of the local market and how we can help meet their needs.

For instance, with Midori-chan, we have been successful in Hong Kong. We have been there for over ten years now and we got some big contracts because water is very precious and expensive there.

We also have other technologies we can license. For example, our 3D welding mask can be applied in every part of the world. We have to work out the details of business, but we can have a good relationship with companies anywhere in the world. We don’t need to establish our own entity. The only place where we are right now is India. We have a representative office, but we work with the local engineering companies because we have a shortage of engineers and India has amazing engineers that can help our needs here, so it’s a very good situation for everyone.

If we were to interview you again on your last day as the president, what goals do you have that you would like to achieve by then?

I became the president when the company was in terrible shape and people were quitting and unhappy. There was a lot of dread that I could see and we had some quality problem caused by it. As we got better, I came up with this idea called Kawada Vision which I originally made it for our 100th anniversary, which was three years ago. Kawada Vision was to make Kawada Group companies to be ones that everybody wants to exist, i.e., our group companies’ business activities are essential to the society. I also want the Kawada Group to be financially solid and I want our engineers and salespeople and everyone that work for us to be proud to be working for the company and I want our customers to be happy. I also want banks to gladly lend us money. I also want institutional investors to agree with our business philosophy and are happy to invest in us. So, by the day I retire, I hope I have achieved all of that.

For more information, please visit their website at: https://global.kawada.jp/ • https://www.kawada.jp/global/