Digital twin technology aimed specifically at improving the efficiency of managing relocatable modular buildings (RMBs) has been developed by researchers at a South Korean university.

The facility management system is said to yield a number of benefits for RMB lifecycle management. RMBs are a sustainable construction method in which buildings are assembled and easily transported using prefabricated modules.

These buildings can be quickly assembled from prefabricated “modules” and easily transported, minimising costs and environmental impact while providing safer and cleaner construction environments.

While an important step for the environmentally construction of buildings and dwellings, RMBs present significant challenges in their management and logistics, hindering their wider adoption.

Researchers from the School of Architecture & Architectural Engineering at Hanyang University ERICA in South Korea have now developed an innovative digital twin facility management system tailored specifically for RMBs. This system integrates technologies to enhance management efficiency throughout a building’s lifecycle.

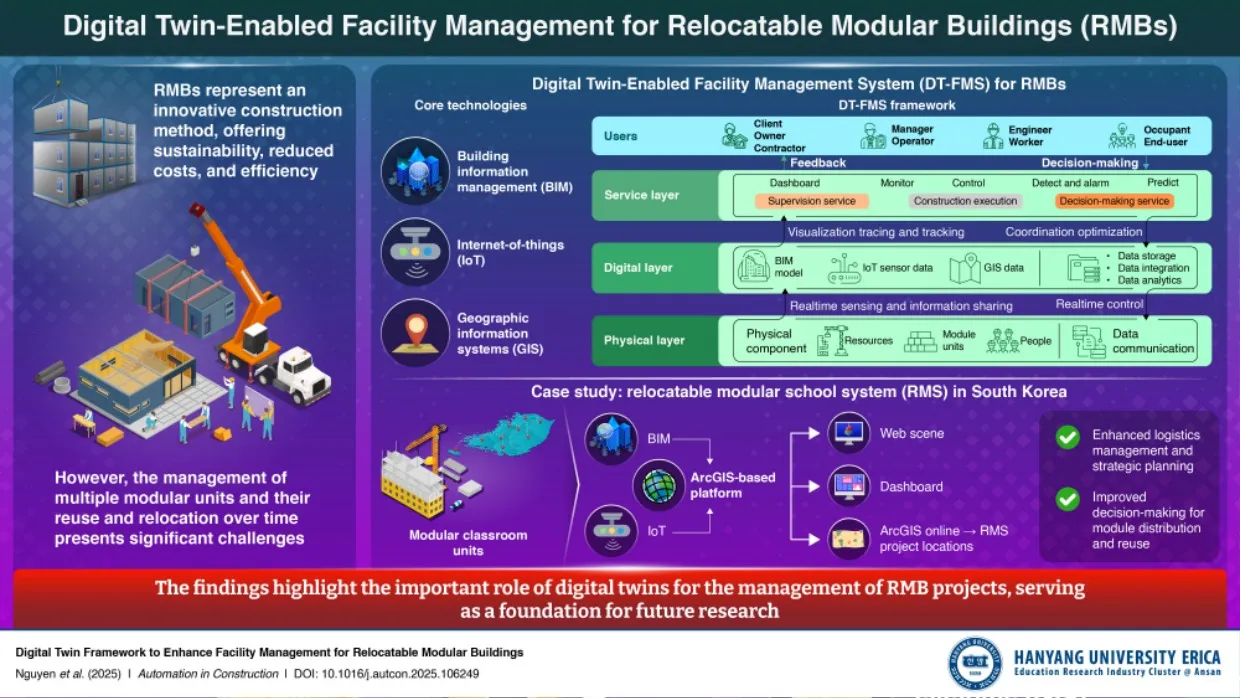

The new digital twin software integrates building information modeling (BIM), internet of things (IoT) and geographic information systems (GIS) to create a detailed virtual model of RMBs. This model supports real-time monitoring, performance analysis and logistics simulations across the building’s lifecycle.

The BIM data is used to offer robust 3D modelling and comprehensive building information while the IoT provides real-time sensor data. GIS contributes critical geographic data but the use of all three sets of data is used to support “effective logistics of modular units and location-based decision making”.

The new management system details across three different layers in the management of buildings, the physical, digital and service layers. The physical layer forms the foundation for real-time tracking and communication among different physical components such as resources, modular unit and people, including stakeholders, engineers and workers. The digital layer includes modelling tools, data integration and analytics. Finally, the service layer allows users to monitor, control and interact with the digital twin framework, supporting effective decision making.

To demonstrate the practical application of the framework, the researchers conducted a case study on a relocatable modular school system in South Korea. The digital twin framework was able to enhance the decision making for module distribution and reuse, resulting in improved management efficiency for the school.

Details from the study were published in Volume 176 of the Journal Automation in Construction on 1 August.

Research lead and Hanyang University associate professor Yonghan Ahn said: “Digital twin technology is a groundbreaking tool that offers a digital replica of physical assets, integrating real-time data, predictive analysis, and decision-making abilities.

“Although digital twins are gaining popularity in other fields, their use in modular construction remains limited. We introduce a novel digital twin-enabled facility management system (DT-FMS) tailored specifically for RMBs.”

Hanyang University professor Dennis Nguyen said: “Our research highlights the important role of digital twins in promoting a circular economy by enabling the reuse, reconfiguration, and optimal relocation of modular units, thereby minimizing waste and maximizing value throughout repeating project cycles.”

Like what you’ve read? To receive New Civil Engineer’s daily and weekly newsletters click here.