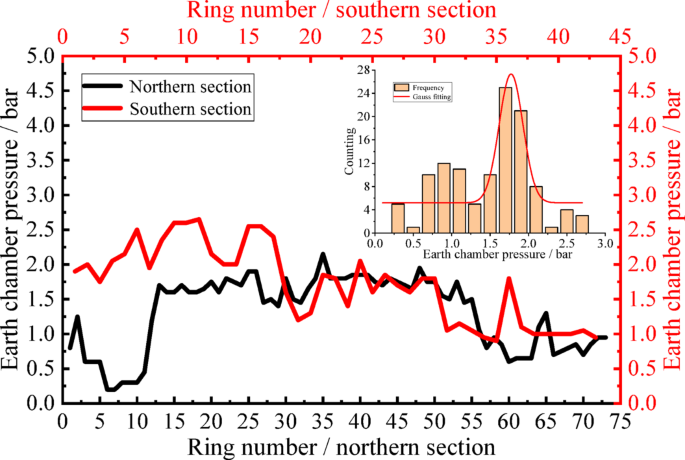

Earth chamber pressure

Figure 5 depicts the time-history curves of the chamber pressure during the quasi-rectangular shield tunneling in the northern and southern sections. The chamber pressure data approximately follows a normal distribution, with a mean of 1.46 bar, a median of 1.55 bar, and a mode of 1.8 bar. The distribution shows that approximately 68.3% of the measured values fall within the confidence interval of 1.5 to 1.8 bar. The pressure exhibits an irregular fluctuation trend, which is attributed to the combined effects of the stratum properties, the chamber pressure control mechanism, and adjustments in the tunneling parameters. In the initial stage, soil disturbance was minimal, but an imbalance existed between the advance rate and the muck discharge. During the middle and later stages, the soil in front of the cutterhead was compressed, leading to stratum deformation and gradual soil consolidation, which resulted in a progressive increase in chamber pressure. In the final stage, the muck discharge rate via the screw conveyor was increased to prevent excessive pressure, consequently reducing the soil volume in the chamber and lowering the pressure.

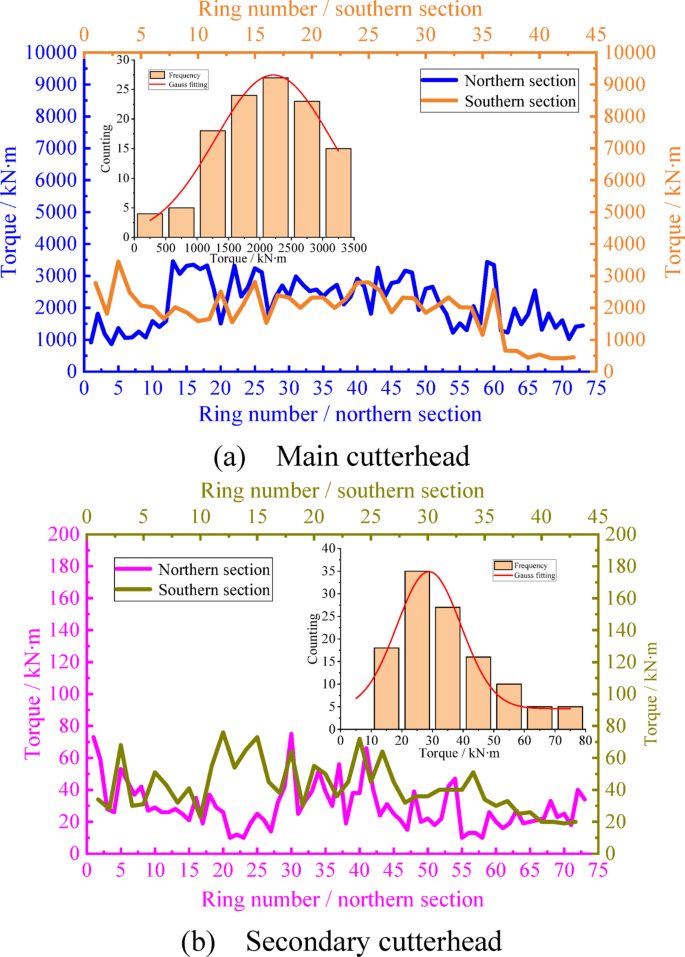

Cutterhead torque

Figure 6 shows the time-history curves of the cutterhead torque during the quasi-rectangular shield tunneling in the northern and southern sections. For the main cutterhead, the average torque was 2073.603 kN·m with a median of 2065.6 kN·m, and the measured data predominantly fell within the range of 1800 to 2400 kN·m. The small cutterhead had an average torque of 34.707 kN·m and a median of 31.5 kN·m, with most measurements distributed between 20 and 40 kN·m. The spoke-type cutterhead exhibits significant torque fluctuations in water-rich sandy strata. This is because its large opening ratio, while beneficial for soil flow and earth pressure balance, also makes the torque more susceptible to ground heterogeneity, leading to pronounced variations during excavation.

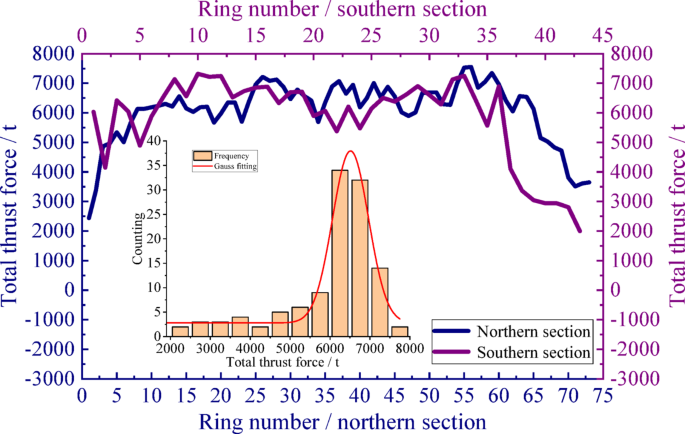

Total thrust

Figure 7 illustrates the time-history curves of the total thrust force during the quasi-rectangular shield tunneling in the northern and southern sections. The total thrust data approximately follows a normal distribution, with a mean value of 5986.017 tonnes, a median of 6338 tonnes, and a confidence interval ranging from 5600 to 7000 tonnes. The overall variation of the total thrust demonstrates an evolution characteristic of “initial increase, followed by stabilization, and final decrease,” which is primarily related to changes in stratum resistance, the working state of the shield machine, and adjustments in tunneling parameters.

Initial Stage: High stratum resistance requires the cutterhead to overcome the initial soil resistance, necessitating an increased thrust to maintain earth pressure balance.

Middle Stage: As the shield machine advances continuously, the stratum resistance tends to stabilize. With the optimization of tunneling parameters, the shield machine enters an efficient tunneling state, resulting in reduced thrust fluctuations.

Final Stage: To prevent excessive chamber pressure, the muck discharge is reduced, leading to a decrease in chamber pressure and, consequently, a reduction in the required thrust.

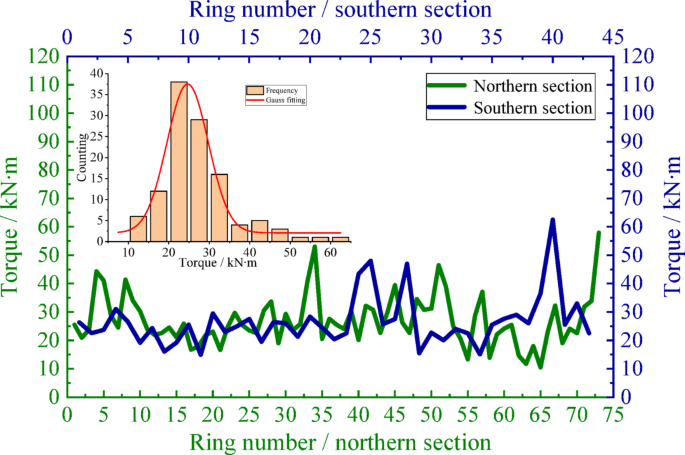

Screw conveyor torque

Figure 8 shows the time-history curves of the screw conveyor torque during the quasi-rectangular shield tunneling in the northern and southern sections. The screw conveyor torque approximately follows a normal distribution, with a mean value of 26.891 kN·m and a median of 24.6 kN·m. The data distribution indicates that approximately 68% of the measured values are concentrated within the confidence interval of 16 to 32 kN·m. The overall variation of the screw conveyor torque is mainly related to the stratum characteristics, the operational state of the screw conveyor, and the effectiveness of soil conditioning.

Initial Stage: Due to the high density and large particles of the water-rich sandy stratum, the initial resistance is significant, leading to an increase in torque demand.

Middle Stage: As the shield machine continues to advance, the conditioning materials (such as foam, bentonite slurry, etc.) are fully mixed with the soil, improving the flow-plasticity characteristics of the muck. This enhances the conveying efficiency of the screw conveyor, resulting in stabilized torque.

Final Stage: Changes in the stratum, such as increased water content in the sandy layer and higher soil density, lead to increased soil resistance, causing the screw conveyor torque to rise again.

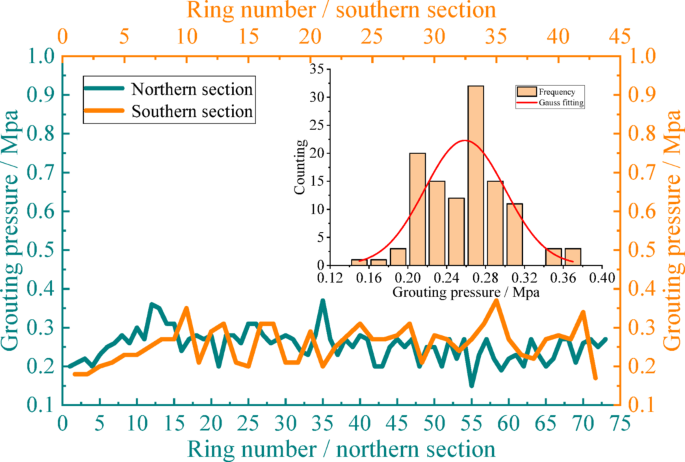

Grouting pressure

Figure 9 presents the time-history curves of the grouting pressure during the quasi-rectangular shield tunneling in the northern and southern sections. The grouting pressure data approximately follows a normal distribution, with a mean value of 0.26 MPa and a median of 0.27 MPa. The data distribution shows that the measured grouting pressures are primarily concentrated within the range of 0.26 to 0.28 MPa. The overall fluctuation of the grouting pressure is relatively small, exhibiting a stable pattern. This stability is mainly attributed to the construction process, stratum characteristics, and precise control of grouting parameters. The high groundwater pressure in the water-rich sandy stratum balances the grout pressure during injection, preventing sudden pressure fluctuations. Furthermore, the accurate control of the grouting volume per ring ensures uniform filling of the tail void, minimizing pressure variations caused by insufficient or excessive grouting.

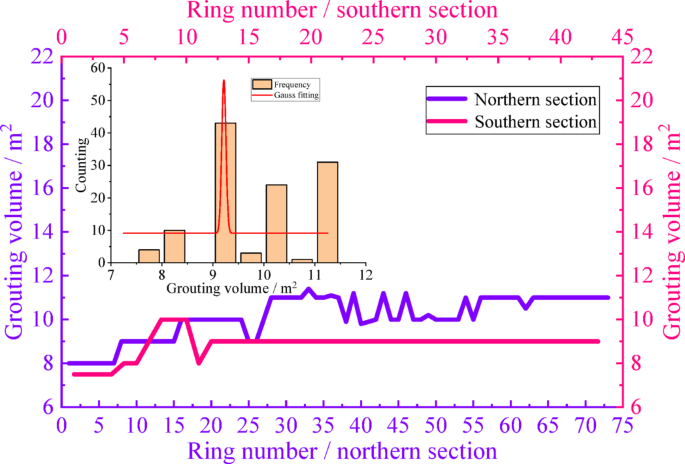

Grouting volume

Figure 10 shows the time-history curves of the grouting volume during the quasi-rectangular shield tunneling in the northern and southern sections. The grouting volume has a mean value of 9.739 m3 and a median of 10 m3. The data distribution indicates that the measured values are mainly concentrated in the range of 9 to 10 m3. The grouting volume exhibits relatively stable variation with minor fluctuations. This parameter is closely related to the grouting pressure and is similarly influenced by the construction process, stratum characteristics, and control of grouting parameters. The precise control of the grouting volume per ring ensures uniform filling of the tail void, reducing issues associated with insufficient or excessive grouting.

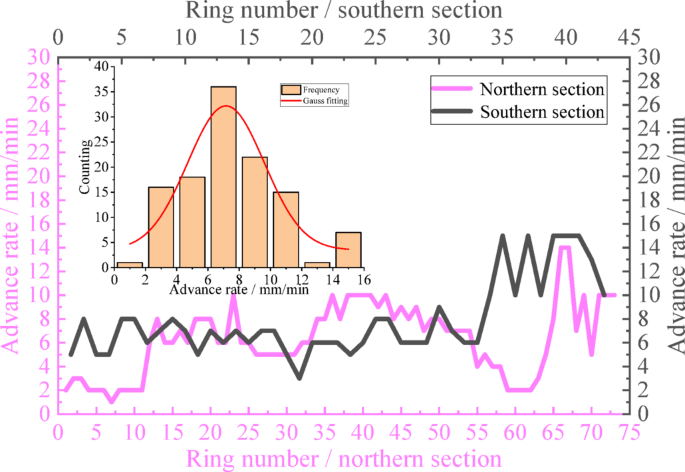

Advance rate

Figure 11 illustrates the time-history curves of the advance rate during the quasi-rectangular shield tunneling in the northern and southern sections. The advance rate approximately follows a normal distribution, with a mean value of 7.009 mm/min and a median of 7 mm/min. Data distribution shows that approximately 45% of the measured advance rate values fall within the confidence interval of 6.0–9.0 mm/min. The overall advance rate exhibits a dynamic trend of “slow initially, then stable, and finally accelerated,” which is closely related to factors such as ground adaptability and adjustments in construction parameters. Initial Stage: The advance rate was relatively slow to allow time for stress release in the formation and to avoid ground collapse. Middle Stage: As tunneling progressed, the ground gradually adapted to the cutting action of the cutterhead, resulting in reduced ground disturbance and a stabilized advance rate. Final Stage: The injection volume and mixture ratio of the soil conditioning agents were optimized, significantly improving muck flowability, which reduced cutterhead torque and tunneling resistance, thereby increasing the advance rate.