Smart laser cutter system detects different materials

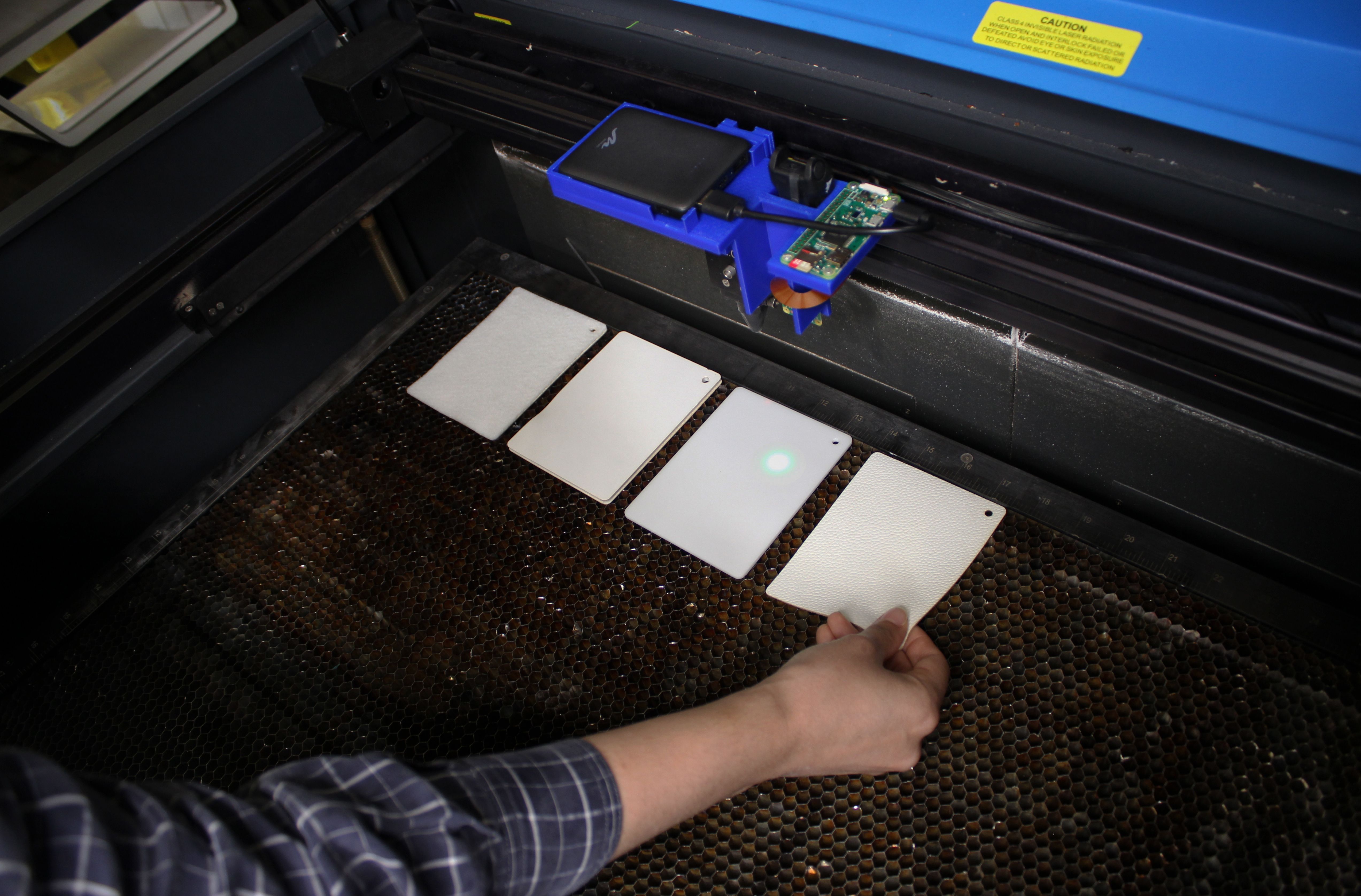

SensiCut, a smart material-sensing platform for laser cutters, can differentiate between 30 materials commonly found in makerspaces and workshops.

With the addition of computers, laser cutters have rapidly become a relatively simple and powerful tool, with software controlling shiny machinery that can chop metals, woods, papers, and plastics. While this curious amalgam of materials feels encompassing, users still face difficulties distinguishing between stockpiles of visually similar materials, where the wrong stuff can make gooey messes, give off horrendous odors, or worse, spew out harmful chemicals.

Addressing what might not be totally apparent to the naked eye, scientists from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) came up with “SensiCut,” a smart material-sensing platform for laser cutters. In contrast to conventional, camera-based approaches that can easily misidentify materials, SensiCut uses a more nuanced fusion. It identifies materials using deep learning and an optical method called “speckle sensing,” a technique that uses a laser to sense a surface’s microstructure, enabled by just one image-sensing add-on.

A little assistance from SensiCut could go a long way — it could potentially protect users from hazardous waste, provide material-specific knowledge, suggest subtle cutting adjustments for better results, and even engrave various items like garments or phone cases that consist of multiple materials.

With the addition of computers, laser cutters have rapidly become a relatively simple and powerful tool, with software controlling shiny machinery that can chop metals, woods, papers, and plastics. While this curious amalgam of materials feels encompassing, users still face difficulties distinguishing between stockpiles of visually similar materials, where the wrong stuff can make gooey messes, give off horrendous odors, or worse, spew out harmful chemicals.

Addressing what might not be totally apparent to the naked eye, scientists from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) came up with “SensiCut,” a smart material-sensing platform for laser cutters. In contrast to conventional, camera-based approaches that can easily misidentify materials, SensiCut uses a more nuanced fusion. It identifies materials using deep learning and an optical method called “speckle sensing,” a technique that uses a laser to sense a surface’s microstructure, enabled by just one image-sensing add-on.

A little assistance from SensiCut could go a long way — it could potentially protect users from hazardous waste, provide material-specific knowledge, suggest subtle cutting adjustments for better results, and even engrave various items like garments or phone cases that consist of multiple materials.

news.mit.edu